The combination of high strength, flexibility, and versatility makes steel one of the most important materials in various industries. Many large-scale projects, for example, couldn't exist without a reasonable amount of this material, including some of its variations. For example, you'll find square steel bars in many more spaces than you might think.

As with many types of metal, steel can be used for a variety of purposes, depending on its composition and shape. A simple square bar is enough to add a little depth to this resource, especially if you're working on a complex project and need something that meets very specific needs.

To help you better understand the topic, we'll discuss square steel bars: their types, main applications, advantages, and how to purchase them. Stay tuned.

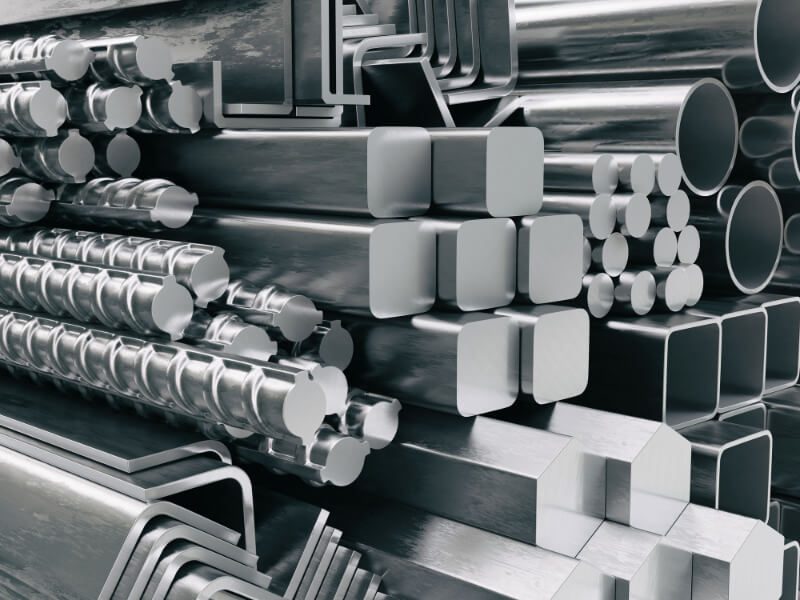

The name itself is pretty self-explanatory. square bar Steel is a simple, solid piece that can be used for a variety of purposes. This is one of the most common shapes, along with other types such as round, hexagonal, and trapezoidal bars. Each of these can be applied in different contexts and for numerous purposes.

This model is usually created shortly after the steel, which is obtained from iron, is prepared. As soon as it leaves the forge, it is shaped to achieve the best shape for transport and use, even if its immediate destination is a more in-depth refinement process.

Much of the versatility of this piece comes from the fact that there are several types of steel, which can be classified according to certain criteria, such as chemical composition, additional elements, and others. In the case of square steel bars, there are four common classifications. See below.

After steel is processed, it most commonly undergoes a rolling process, which reduces its thickness and increases its density, as well as making its surface smoother. To do this, the bars are reheated to a temperature above recrystallization and pressed using metal rollers.

This type of steel bar is widely used in construction. It's a simple and effective format, yet offers plenty of room for modification and adaptation to meet specific project needs. It can be used for both structural and aesthetic design purposes.

An alternative to rolling is wire drawing, which also aims to reduce the thickness of the metal and make it denser. The main difference is that, instead of heating the steel, the bar goes through all the compression with only a mechanical effect, something that gives the part unique mechanical properties.

Due to these properties and finish, drawn bars are widely used in the manufacture of nuts, bolts, pins, and other similar fitting parts. This is especially important for materials used in the manufacture of heavy machinery and vehicles, which require maximum strength in all their parts.

Alternatively, instead of compressing the metal into the desired shape, it's possible to debark it, removing the top layer of the material to eliminate imperfections. This preserves some of its properties, such as lower density, which is important in some applications.

Of course, in many cases, stripped steel may have some defects, whether aesthetic or functional. In these cases, after stripping, the square steel bar may also undergo a polishing process, in which any remaining surface flaws are removed.

The great advantage of these bars is that they are highly resistant to corrosion, as there are no grooves that would allow impurities to enter. As a result, this is one of the most cost-effective options for most projects, as these parts require much less frequent replacement.

As the name suggests, this is a type of steel made from two other types, carbon steel and alloy steel. Each ingot is heated and compressed until its basic structure changes, resulting in a square bar of forged steel.

The complete manufacturing process tends to be more complex and time-consuming, as they still require processing after compression. However, the result is a material with unique qualities, widely used in the mechanical industry.

The simplest part is often the most useful in different contexts. Just look at the various roles a steel bar can fulfill if used correctly. Check out some of the main examples of how it's used here.

As you can imagine, square bars are widely used in civil construction, mainly as a base for making structural steelIt is an essential material for the integrity of larger buildings, as it provides flexibility to the structure, distributing its weight and avoiding points of weakness.

Another common application is the preparation of prefabricated structures, which can be transported directly to the construction site. This is a very common practice on large projects, as it significantly reduces the time needed to complete construction.

Another sector that makes extensive use of square steel bars is industry. They serve as a raw material for the construction of various other objects, such as tools, automobile parts, and more. It's not uncommon to find countless industrialized products, especially in the technology sector, that use steel as a base.

Depending on what will be manufactured, the industry in question may request steel bars with different dimensions, each with specific qualities to ensure the best quality for the final product.

Of course, sometimes all that's needed to get the most out of steel is to shape it into the ideal shape for use. This is the case with metalworking, which involves modifying the material and transforming it into usable parts, such as gates, windows, and other similar metal structures.

Metalworking can be performed by any qualified professional, whether as a sole proprietor, a microenterprise, or another enterprise. Therefore, it's quite common to find some businesses requesting quality steel for their work, both for manufacturing and maintenance.

The use of square steel bar offers several benefits, whether in industry or civil construction. Learn, below, some of its greatest qualities.

As mentioned, steel is a material used in a variety of contexts, whether for practical, structural, or aesthetic purposes. In many cases, it's the only material capable of meeting all the demands of the task, which further increases its value.

It's precisely this wide range of applications that makes it such a common material. A simple bar can be used to build a foundation, repair flaws in a structure, or as an aesthetic finish.

The wide variety of steel grades is another advantage of this material. As you can see, each bar can undergo a different refinement process, each affecting some of its properties and, consequently, its application context.

However, even after this entire process, it's very likely that the steel can still be modified in some way, whether in its shape or with additional components. The result is a highly flexible material, ideal for meeting very specific demands.

THE steel resistance, often speaks for itself. Even the least resistant models are capable of withstanding great pressure without giving way. An indispensable quality when it comes to metal structures or large machinery.

In addition to withstanding friction and physical pressure, there are several types of steel that better resist corrosion. This is the case, for example, with stainless steel, used in areas that are more exposed to elements such as wind and rain.

In many environments, but especially in industry, the materials used must be able to withstand extreme temperatures, both hot and cold. Otherwise, they would quickly lose their integrity, eliminating their usefulness and posing safety risks.

Once again, steel is one of the most obvious solutions, as it can withstand extreme temperatures without significant damage. And even when there are rapid temperature changes, it has a good chance of not deforming.

When it comes to large-scale constructions, such as apartment buildings, it's important to consider the long-term return on investment for each material. At this point, durability becomes as important as appearance or short-term strength, as the goal is to minimize the need for maintenance.

This is why the construction industry makes extensive use of square steel bars. They can be used to create metal skeletons and support various structures. structures. And its long service life makes it ideal for withstanding all this pressure without creating safety risks.

Of course, to ensure your project makes the most of square steel bars, you need to find a reputable supplier. If you're looking for this, know that you can count on Grupo Aço Cearense to find high-quality parts without any hassle.

Check out some of the benefits of purchasing from Grupo Aço Cearense.

One of the first things to consider when purchasing steel is its quality. Ideally, it should be highly refined, eliminating any unwanted components that could reduce its durability and effectiveness during application. This requires a series of processes to achieve the ideal result.

For this reason, Grupo Aço Cearense works only with top-tier partners in the steel production and refining industry. Extreme care is taken, from the selection of iron for manufacturing to the in-depth quality control of all parts.

Even with all the quality steel in the world, it doesn't make much difference to the buyer if they can't place their order quickly or have their questions answered quickly. The more headaches there are during the purchasing process, the more the project is delayed.

Naturally, the Aço Cearense Group also works to avoid any inconveniences. Everything from our customer service to your service request budget and order delivery, is designed for maximum efficiency.

Count on one supplier Experience in the steel market also makes a big difference in all its qualities. The longer the experience, the better prepared they tend to be to deal with unforeseen events without losing sight of the quality of service to the customer.

With over 40 years of experience, Grupo Aço Cearense boasts a diverse workforce of qualified professionals in the industrial sector, spanning extraction, production, and logistics. A business model refined by the expertise of its employees spanning decades.

Material accessibility is also an important factor in any project. The square steel bar must not only be of high quality but also be available in the quantity required for the project.

With Grupo Aço Cearense, you won't have that problem. Our members and representatives are spread across the country, opening up opportunities for our clients, regardless of their location. Simply check our list of partners and find the one closest to you.

We saw, throughout the post, the applications of the square steel bar and its technical specifications. Its use is so versatile that it is widely used in metalworking, industrial, construction, and other sectors.

So, now you understand all the specifics of square steel bars, their advantages, and how to find a good supplier. Grupo Aço Cearense always guarantees the highest quality to all our customers, both in products and service.

Don't wait any longer! Visit our product catalog and request a quote with the Aço Cearense Group right now.